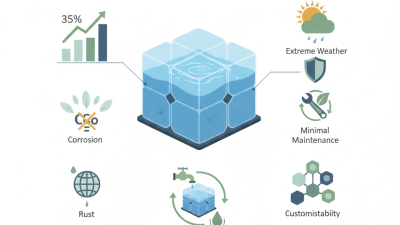

In recent years, the use of SMC tanks has gained significant traction across various industries. These tanks are made from sheet molding compound, a durable and lightweight material. Their unique properties contribute to efficiency in many applications.

Industries such as water treatment, chemical storage, and agriculture benefit greatly from SMC tanks. The corrosion resistance of these tanks prolongs their lifespan. Reduced maintenance costs are another advantage. However, the initial investment can be a concern for some businesses.

Despite this, the advantages outweigh the drawbacks for many users. SMC tanks provide excellent thermal insulation. They are also easy to transport and install. As industries evolve, the adaptability of SMC tanks remains a crucial factor in their growing popularity.

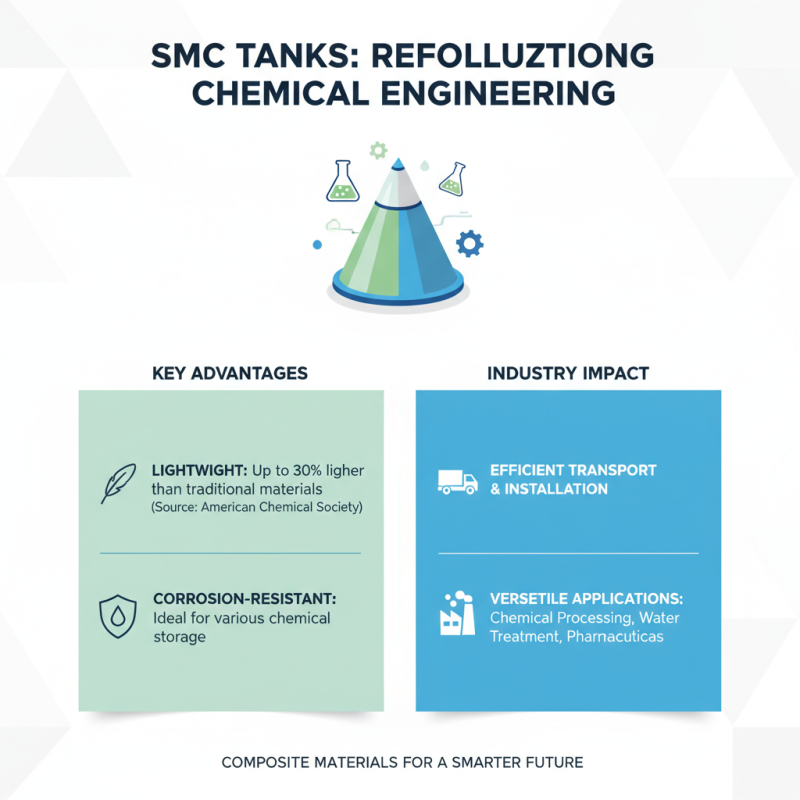

SMC (Sheet Molding Compound) tanks are revolutionizing the chemical engineering industry. These tanks are lightweight and resistant to corrosion, making them suitable for various chemical storage applications. According to a report by the American Chemical Society, the use of composite materials in manufacturing tanks can reduce weight by up to 30%. This characteristic is particularly beneficial for industries where transport and installation are crucial.

In chemical processing, SMC tanks offer significant advantages. They can withstand harsh chemicals without degrading, unlike traditional metal tanks. This leads to lower maintenance costs. A study from the Chemical Engineering Journal highlights that corrosion-related failures account for nearly 40% of downtime in chemical plants. Investing in SMC tanks can mitigate this issue. However, the initial cost of these tanks can be higher than conventional options, which might deter some operators.

Another key benefit is the versatility of SMC tanks. They can be molded into various shapes and sizes, accommodating different industry needs. The flexibility in design allows for custom solutions, but ensuring standards in quality control is challenging. A lapse here can lead to safety issues. Thus, while SMC tanks present great benefits, continuous evaluation and improvement in manufacturing processes remain essential.

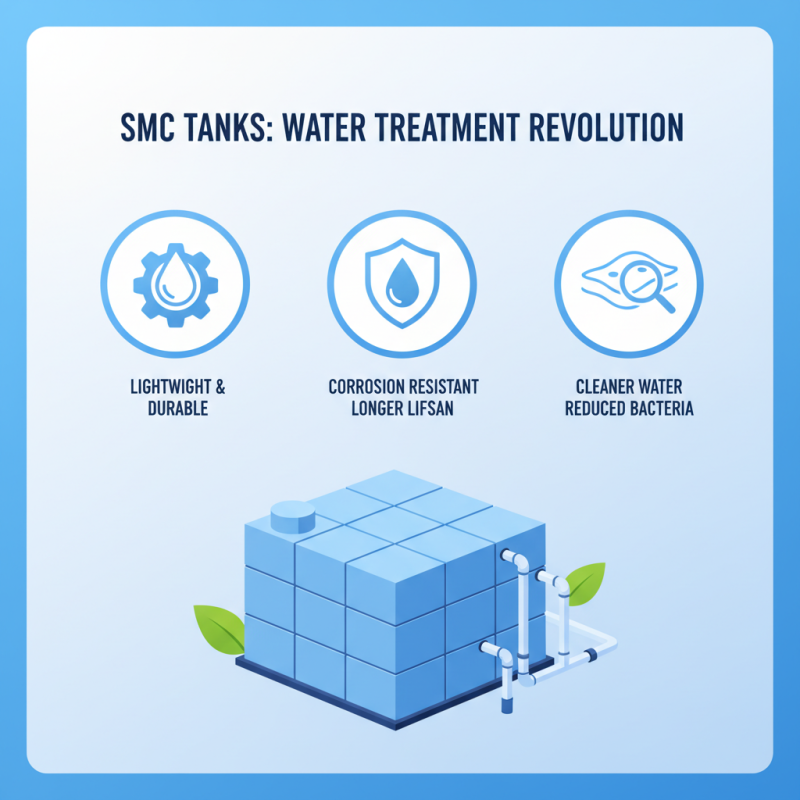

SMC tanks, known for their lightweight and durable nature, are transforming water treatment facilities. These tanks withstand corrosion, making them an ideal choice for storing water. Unlike traditional materials, SMC offers a longer lifespan, reducing replacement costs. The smooth interior surface minimizes bacterial growth, ensuring cleaner water for treatment processes.

Moreover, SMC tanks are easy to install and maintain. Their modular designs allow for flexible configurations, fitting various spatial requirements. This adaptability can sometimes lead to installation challenges in tightly spaced facilities. However, teams often find creative solutions to work around such issues.

Another advantage is the insulation properties of SMC. This feature helps maintain consistent water temperature, which is crucial for effective treatment. Nevertheless, not all facilities may benefit equally, as temperature fluctuations can still occur depending on external conditions. Overall, SMC tanks represent a significant step forward in enhancing efficiency and reliability in water treatment.

SMC tanks are revolutionizing food and beverage manufacturing.

These tanks offer advantages in terms of durability and hygiene.

For instance, SMC materials are resistant to corrosion and do not leach harmful substances.

According to a 2022 industry report, improper tank materials can lead to 10-20% product loss due to contamination.

Using SMC tanks can significantly reduce this risk.

In addition, SMC tanks provide excellent insulation properties.

This is crucial in temperature-sensitive processes, like dairy or brewing. Effective temperature control can enhance flavor and quality.

However, many manufacturers struggle to understand the longevity of SMC compared to traditional materials.

Some reports indicate that SMC can last twice as long, reducing replacement costs.

Not all industries have fully embraced this technology. Some still prefer conventional metal tanks due to initial investment concerns.

There can also be a lack of education about the benefits of SMC. In the long run, companies could face higher costs due to frequent maintenance.

Transitioning to SMC tanks may seem daunting, but the potential for improved efficiency and product integrity is significant.

Each industry should evaluate its specific needs carefully.

The cost efficiency of SMC tanks in construction projects is noteworthy. SMC, or Sheet Molding Compound, is known for its durability and lightweight properties. According to a recent industry report, using SMC tanks can reduce construction costs by up to 30%. This reduction primarily comes from lower transportation costs and easier installation.

Construction sites are often congested. Using lightweight SMC tanks simplifies handling and saves time. Labor requirements are minimized due to the ease of installation. A study by a construction trade association noted that labor savings can reach 20% with SMC tanks. Additionally, fewer materials are needed for support structures, leading to even more savings.

**Tip:** Always assess the specific requirements of your project. SMC solutions may not fit every situation. Consult with industry experts to ensure suitability.

Another interesting fact is that SMC tanks require less maintenance than traditional options. This can lead to long-term savings. Some may argue that initial costs are higher. However, when considering the life cycle costs, SMC often proves advantageous. Keep in mind that not all projects benefit equally. Be thoughtful in the selection process.

**Tip:** Review case studies for similar projects. They can provide valuable insights into cost efficiency and long-term reliability.

SMC tanks are gaining popularity due to their environmental advantages. These tanks are lightweight and durable, which helps reduce transportation emissions. According to a study from the Environmental Protection Agency, using composite materials like SMC can lower carbon emissions by up to 30% compared to traditional metal options.

In addition to emissions reduction, SMC tanks are corrosion-resistant. This quality minimizes the need for harmful coatings or treatments during manufacturing. A report from the National Institute of Standards and Technology highlights that reducing chemical runoff from containers is crucial for protecting water sources. SMC tanks contribute to this goal.

Yet, it's important to reflect on the production process of SMC tanks. While they offer numerous benefits, fabrication processes might still involve energy-intensive procedures. Sustainable practices in production can further enhance their environmental impact. Monitoring these procedures remains vital for continuous improvement in sustainability efforts.