Choosing the right Fire Water Storage Tank is crucial for any facility. It plays a significant role in fire protection strategies. Selecting an appropriate tank can be daunting, especially with various options available.

There are multiple factors to consider, such as capacity, material, and location. Each aspect affects performance and reliability. It's essential to evaluate your specific needs carefully. A tank that works for one facility may not suit another.

Many people overlook maintenance requirements and compliance standards. This can lead to unexpected challenges. Understanding local regulations is important to ensure effectiveness. A well-chosen Fire Water Storage Tank can make a difference in emergencies. However, making the wrong choice can be costly. Taking time to reflect on these points is vital.

Fire water storage tanks play a crucial role in safety planning. They provide a reliable source of water for firefighting activities. In emergencies, having access to water can make all the difference. Every facility should assess its fire water needs carefully.

When choosing a tank, several factors must be considered. The size of the tank matters, as it should accommodate your specific requirements. Local regulations often dictate minimum capacities.

Placement also plays a role. Tanks should be strategically located for quick access. A buried tank might seem ideal, but it can lead to challenges in maintenance and visibility.

Not everyone realizes the importance of regular inspections. Tanks can develop leaks or corrosion, risking water availability. Understanding fire water storage capacity is essential in an emergency.

Planning without thorough analysis may lead to inadequate resources. Each decision influences overall safety, and even small oversights can have severe consequences.

When determining the correct capacity for fire water storage tanks, several key factors come into play. Understanding the specific needs of your facility is crucial. A common guideline suggests that a facility requires at least 500 gallons per minute (GPM) for adequate fire protection. However, this can vary widely based on local regulations and the type of risk present. A manufacturing plant may need a larger tank compared to a residential building.

Analyzing the potential fire hazards is important. High-risk areas, such as warehouses storing flammable materials, may necessitate larger tank capacities. For example, reports indicate that systems designed for industrial use often need a minimum of 10,000 gallons of stored water. This often covers the anticipated demand during an emergency situation, which can last several hours.

Consideration of the local climate is also essential. In regions prone to drought, smaller reserves may become insufficient. It's not uncommon for businesses to find themselves caught off-guard when estimating their needs. Many facilities underestimate their requirements, leading to potential dangers. Reviewing historical data on local fire incidents can provide valuable insights.

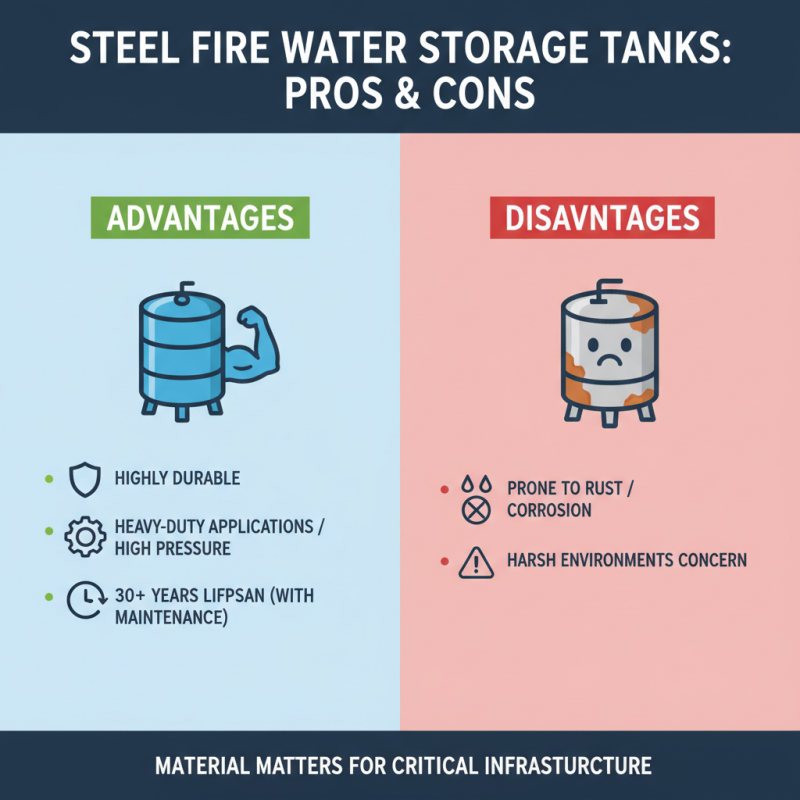

When selecting a fire water storage tank, the choice of material is crucial. Steel tanks are highly durable and suited for heavy-duty applications. They can endure high pressure and are resistant to impacts. According to recent industry reports, steel tanks have a lifespan of over 30 years with proper maintenance. However, they are prone to rust when exposed to harsh environments, which can be a significant concern for long-term use.

Fiberglass tanks offer an alternative. They are lightweight and corrosion-resistant, making them a popular choice for various applications. Recent data suggests they can last about 25 years. They do not rust like steel, but they can be vulnerable to UV damage if not properly protected. Installation can be more complex and might require skilled labor for proper setup.

Polyethylene tanks are the most cost-effective and versatile option. They are resistant to chemicals and UV light, making them suitable for outdoor use. Polyethylene tanks are also extremely lightweight, making transport easier. However, their lifespan is often only around 15-20 years. They might not withstand extreme temperatures as well as steel and fiberglass.Choosing the right tank material requires balancing durability, cost, and environmental conditions. Each option has trade-offs that need careful consideration.

When selecting a fire water storage tank, compliance with regulatory standards is crucial. Various organizations set guidelines for tank design and capacity. For example, the National Fire Protection Association (NFPA) outlines minimum capacity requirements based on occupancy types. Typically, a tank must hold enough water to handle the worst-case scenario for fire protection.

The Environmental Protection Agency (EPA) also impacts storage tank regulations. Depending on location, tanks must comply with specific environmental standards. These standards help prevent contamination of groundwater sources. Each state may have additional regulations that impact tank installation and maintenance. It's essential to check local laws before finalizing your choice.

Not all tanks will meet these standards. Some products may lack certification or rigorous testing. Choosing a non-compliant tank can lead to severe consequences, including fines or legal action. Moreover, improper tank maintenance can violate compliance requirements. Regular inspections and maintenance schedules are key for long-term operation. Understanding these regulations ensures safety and efficiency in fire protection measures.

Regular maintenance and inspection of fire water storage tanks are crucial. Neglecting these tasks can lead to significant issues. A visual inspection should occur at least once a month. Look for corrosion, leaks, or any unusual signs. Small problems can escalate quickly. The sooner you identify them, the better.

Cleaning is another essential part of tank maintenance. Sediment can build up over time, affecting water quality. Consider a thorough cleaning every 6 to 12 months. Using high-water pressure can help remove stubborn deposits. Ensure that all safety protocols are followed during this process.

Testing the water quality is vital. Routine checks for contaminants are necessary to guarantee effectiveness. You cannot afford to compromise safety. Keep a record of inspections and maintenance work. Documentation helps track progress and identify recurring issues. Ignoring these details may lead to future complications with your tank's performance.