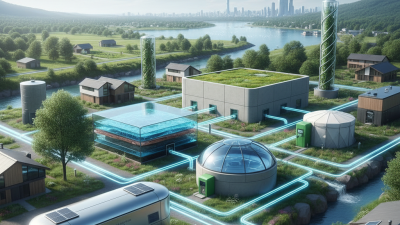

In an era where water conservation and quality storage have become paramount, selecting the right HDG (Hot-Dip Galvanized) Water Tank is essential for meeting diverse water storage needs. According to the Water Research Foundation, improper water storage systems contribute to nearly 20% of water quality issues reported in municipal supplies. This statistic underscores the significance of not only the capacity of water storage solutions but also their material integrity and design. Experts in the industry emphasize the importance of durability and resistance to corrosion, with reputed engineer Dr. James Holloway stating, “Investing in a high-quality HDG Water Tank is not just about storing water; it's about ensuring the water you consume is safe and reliable.”

The rising demand for HDG Water Tanks can be attributed to their overwhelming benefits, including longevity, low maintenance, and enhanced water quality preservation. A report from the International Water Management Institute highlights that using HDG Water Tanks can extend water storage life by up to 50% compared to traditional materials. As industries and households navigate the complexities of water scarcity and contamination, understanding the advantages of HDG Water Tanks becomes crucial. When choosing the right tank, factors such as location, intended use, and capacity must align with the robust characteristics of HDG technology to create an optimal water storage solution.

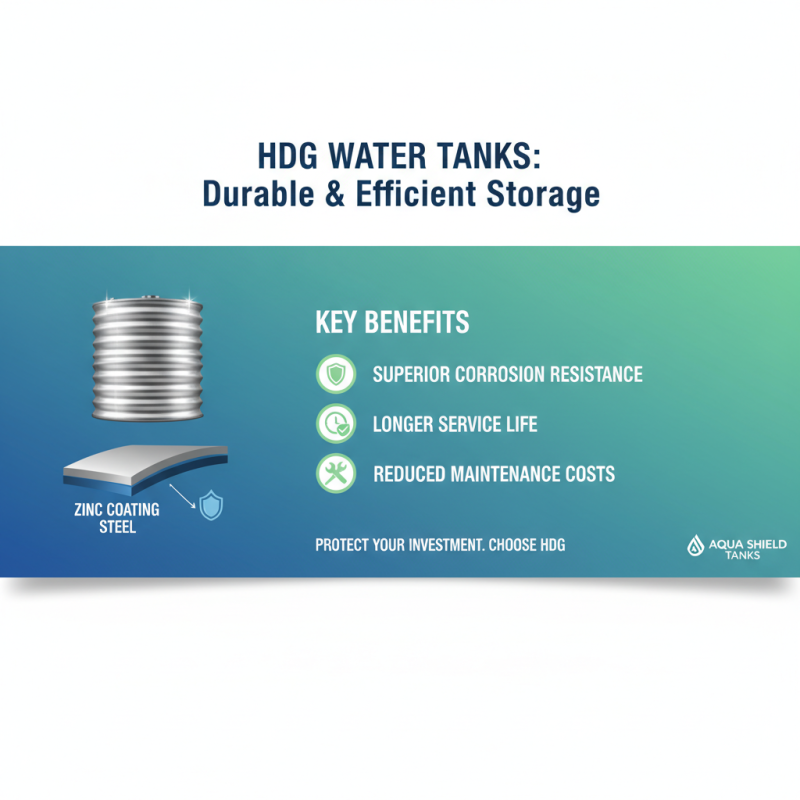

When it comes to water storage solutions, HDG (hot-dip galvanized) water tanks stand out for their durability and efficiency. The process of hot-dip galvanization involves coating steel with a thick layer of zinc, which provides superior corrosion resistance. This is particularly crucial for water tanks, as they are often exposed to moisture and environmental elements that can lead to rust and degradation. By choosing an HDG water tank, homeowners and businesses can ensure that their investment is protected against the elements, leading to fewer maintenance costs and longer service life.

Additionally, HDG water tanks offer versatility in design and capacity, catering to a wide range of storage needs. Whether for agricultural purposes, fire protection, or residential applications, these tanks can be customized to fit specific requirements. Their robust construction also allows them to withstand physical impacts, making them suitable for high-demand environments. Understanding the importance of selecting the right HDG water tank is vital to securing a reliable and long-lasting solution for water storage. Properly assessing one's needs and choosing an HDG tank can significantly enhance the efficiency and safety of water storage systems.

When selecting a hot-dip galvanized (HDG) water tank, several key factors should be carefully considered to ensure it meets your specific water storage needs. First, the capacity of the tank is crucial. It should be based on your daily water consumption and any future expansion plans. Assessing your current and anticipated water usage will guide you in choosing a tank that not only meets your immediate requirements but also accommodates potential increases in demand.

Another important factor is the tank's resistance to corrosion, especially for outdoor installations or in areas with harsh environmental conditions. HDG tanks are specifically designed to withstand rust and deterioration, but it’s essential to check the quality of the galvanized coating and ensure it meets industry standards. Additionally, consider the tank's design and construction features, such as insulation options and compatibility with existing water systems, which can further enhance its performance and longevity.

When evaluating water storage options, it is crucial to compare HDG (hot-dipped galvanized) water tanks with alternative materials like plastic or stainless steel. HDG water tanks offer a unique advantage in terms of durability and resistance to corrosion. The galvanized coating provides a protective layer that prolongs the tank's lifespan, making it an ideal choice for both residential and industrial applications. In contrast, while plastic tanks are lightweight and less expensive, they often lack the resilience needed for long-term outdoor use, especially in extreme weather conditions.

On the other hand, stainless steel tanks are known for their strength and hygiene standards, but they typically come at a higher cost. HDG tanks provide a balanced solution, combining affordability with a robust structure. Their ability to withstand high temperatures and pressure makes them versatile for various storage scenarios. Furthermore, HDG tanks are less prone to UV damage compared to plastic options, which can lead to pre-mature wear and tear. As such, understanding these differences is vital for selecting the right tank that meets both performance and budgetary requirements.

| Water Storage Option | Material | Capacity (Liters) | Corrosion Resistance | Lifespan (Years) | Maintenance Needs | Cost ($) |

|---|---|---|---|---|---|---|

| HDG Water Tank | Galvanized Steel | 5000 | Excellent | 30+ | Low | 1500 |

| Plastic Tank | Polyethylene | 2000 | Good | 15-20 | Moderate | 800 |

| Fiberglass Tank | Fiberglass | 3000 | Very Good | 25-30 | Low | 1200 |

| Concrete Tank | Concrete | 10000 | Fair | 50+ | High | 2500 |

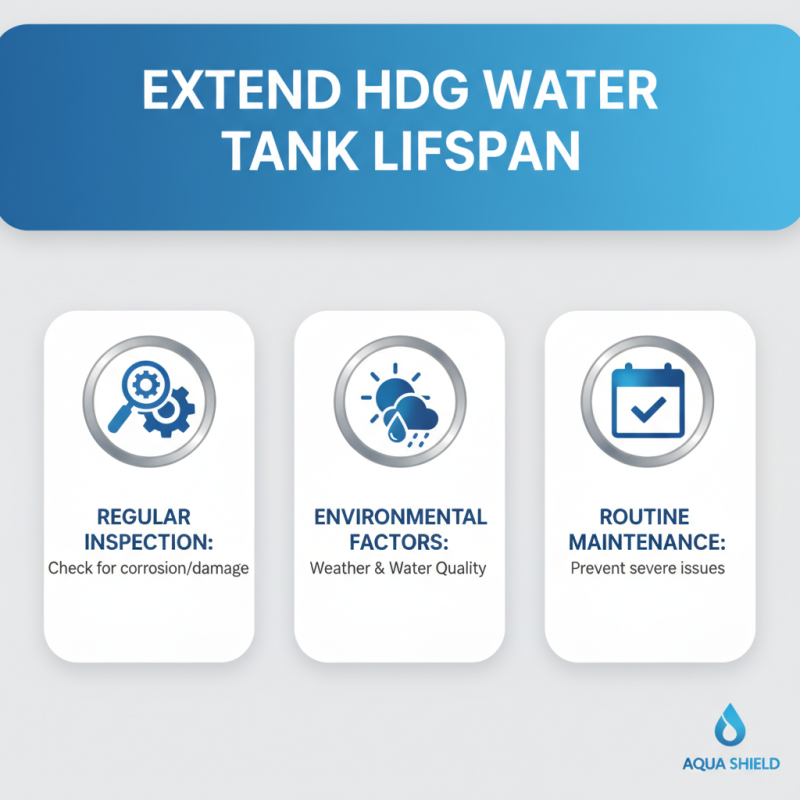

When it comes to the maintenance and longevity of hot-dip galvanized (HDG) water tanks, several key factors come into play that can significantly extend their lifespan. One of the most important aspects is regular inspection for any signs of corrosion or damage. HDG tanks are known for their resistance to rust and corrosion, thanks to the protective zinc coating. However, environmental factors, such as exposure to extreme weather conditions and the quality of the water stored, can still impact their performance over time. Therefore, implementing a routine maintenance schedule that includes visual inspections and assessments can help in identifying issues before they become severe.

Another crucial component of ensuring the longevity of HDG water tanks is proper cleaning and upkeep. Over time, sediment can accumulate at the bottom of the tank, potentially leading to contamination and reduced efficiency. Establishing a regular cleaning protocol that involves draining the tank, removing any residue, and sanitizing the interior can greatly enhance both the water quality and the tank’s overall condition. Additionally, checking and maintaining the seals, fittings, and valves can prevent leaks and ensure a reliable water storage system, thereby enhancing the durability of the HDG water tank in the long run.

HDG (Hot-Dip Galvanized) water tanks are widely used across numerous industries due to their durability and corrosion resistance. One of the most common applications is in agriculture, where they serve as reliable storage for irrigation water. Farmers can store rainwater or groundwater for use during dry seasons, ensuring their crops receive adequate hydration. This is crucial for optimizing crop yields and maintaining sustainable agricultural practices.

In industrial settings, HDG water tanks are utilized for various processes, including cooling systems and fire protection. Their robust construction allows them to withstand harsh conditions, making them suitable for manufacturing plants and chemical processing facilities. These tanks are often used to store water needed for emergency situations or to support production processes that require a consistent water supply.

Tips for choosing the right HDG water tank include assessing the specific needs of your application, such as capacity and location. Additionally, consider the environmental factors that could affect the tank's longevity, such as exposure to extreme temperatures or corrosive substances. Regular maintenance is crucial to ensure your water tank remains in top condition, prolonging its life span and efficiency.