GRP Water Tanks: How Does GRP Tank Installation Work On-Site?

Efficient Water Storage is a cornerstone for industrial, municipal, and agricultural operations. For pump suppliers, firefighting contractors, irrigation companies, water authorities, water purifier providers, and pipe distributors, understandinghow GRP tank installation works on-site is essential. Proper installation ensures durability, leak-free operation, and long-term cost efficiency.

Why GRP Water Tanks Are Popular in Industrial Applications

GRP (Glass Reinforced Plastic) Water Tanks combine the strength of fiberglass with the durability of polymer resin, providing a lightweight yet resilient solution for diverse water storage needs. Key advantages include:

-

Corrosion resistance – Ideal for industrial environments and areas with high moisture or chemical exposure

-

Lightweight modular design – Easier transportation, rooftop installation, and on-site assembly

-

Safe potable water storage – Meets industry and municipal standards for clean water

-

Long-lasting performance – Minimal maintenance and high durability under variable temperatures

These benefits make Grp Water Tanks a go-to choice for industrial buyers looking for reliable water storage solutions.

Step-by-Step Guide: How Does GRP Tank Installation Work On-Site?

Installing a GRP tank on-site involves careful planning and execution. The process typically follows these key steps:

1. Site Assessment & Foundation Preparation

Before installation begins:

-

Evaluate the site for stability, accessibility, and load-bearing capacity

-

Construct a level concrete foundation or reinforced platform

-

Plan for adequate drainage to prevent water accumulation at the base

A well-prepared foundation is critical to prevent structural issues and ensure the tank’s long-term reliability.

2. Delivery and Inspection of Materials

GRP tanks are delivered in modular panels for easier transport. On arrival:

-

Inspect panels for cracks, dents, or defects

-

Verify all accessories are present: bolts, gaskets, sealants, and vents

Proper inspection helps avoid delays and ensures the tank will function correctly once assembled.

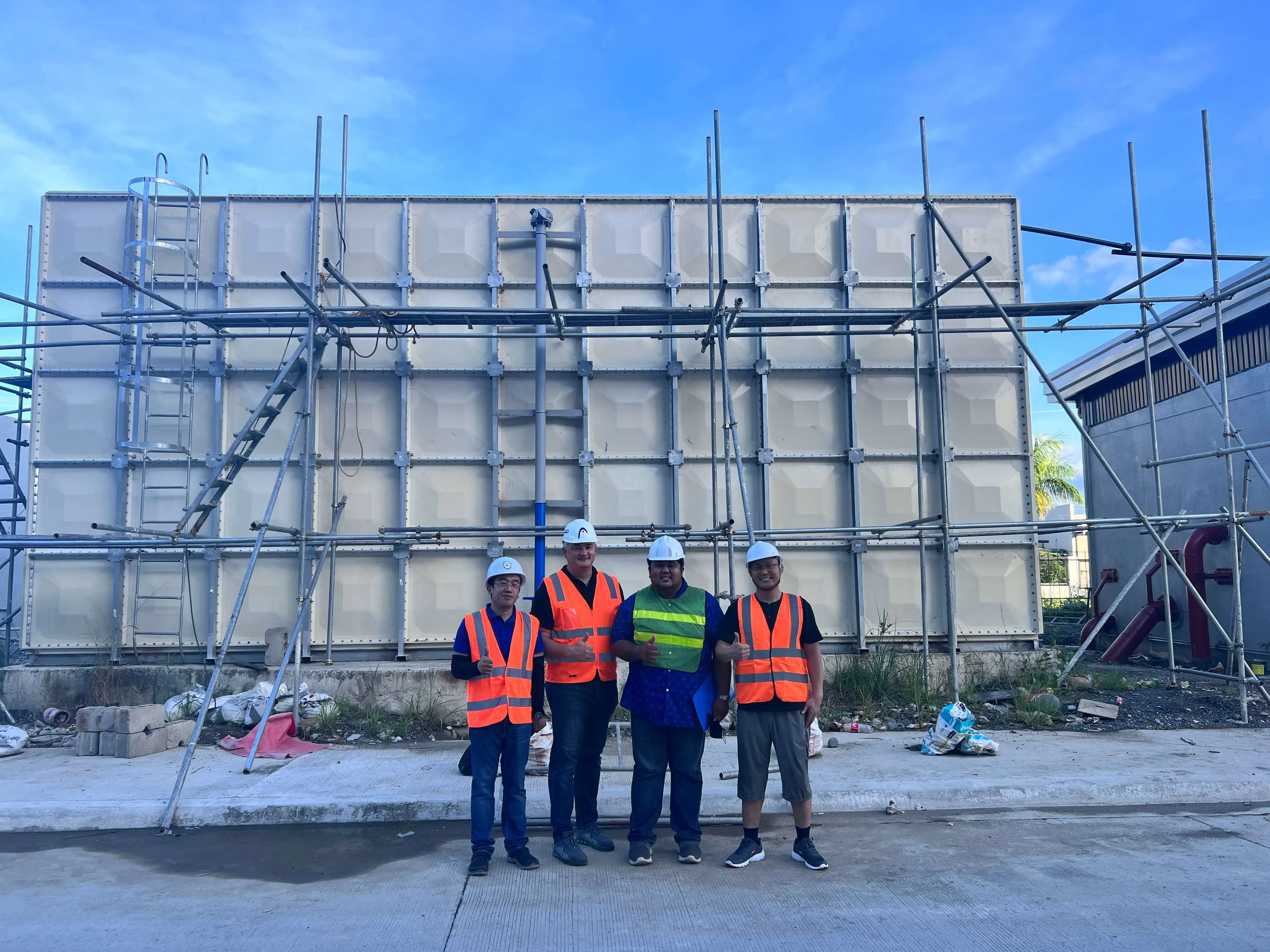

3. Assembly of Modular Panels

On-site assembly usually follows these steps:

-

Lay the base panels on the prepared foundation

-

Bolt wall panels together, applying gaskets or silicone sealants at joints

-

Install internal bracing or tie-rods for structural stability

-

Complete the roof panels, including inspection hatches if required

Modular construction makes it easier to install tanks in confined or urban locations without heavy machinery.

4. Plumbing Connections

After assembly, the tank is connected to the water system:

-

Inlet pipes – Connecting pumps, boreholes, or municipal mains

-

Outlet pipes – Feeding irrigation systems, industrial equipment, or fire protection systems

-

Overflow and venting – Ensuring safe pressure release and preventing flooding

All joints must be carefully sealed to handle variable water pressures.

5. Testing and Commissioning

Before full operation, conduct thorough quality checks:

-

Leak testing – Partial filling to ensure no seepage

-

Structural verification – Confirm internal bracing and panels remain stable

-

System integration – Test inlet/outlet flow and compatibility with pumps or treatment systems

Once tests are successful, the tank is ready for use.

Practical Applications of GRP Water Tanks

GRP tanks serve multiple industrial purposes:

-

Fire Protection – Emergency water reserves for commercial and industrial facilities

-

Agricultural Irrigation – Reliable water storage for farms, nurseries, and irrigation systems

-

Municipal and Industrial Supply – Buffers water for treatment plants, factories, and municipal pipelines

-

Water Purification & Treatment – Safe storage for potable water or treated water systems

Their modularity and corrosion resistance make them highly versatile across industries.

Benefits of On-Site GRP Tank Installation

-

Cost-efficient shipping – Lightweight panels reduce transport costs

-

Customizable sizes – Modular design allows adaptation to site-specific needs

-

Fast installation – Most tanks assemble within 3–7 days

-

Low maintenance – Resistant to UV, temperature variations, and chemicals

-

Flexible placement – Suitable for rooftops, basements, and tight industrial spaces

These advantages make GRP tanks a practical, long-term investment for industrial buyers.

Understanding how GRP tank installation works on-site is essential for pump suppliers, firefighting contractors, irrigation companies, water authorities, water purifier providers, and pipe distributors. Proper planning, site preparation, panel assembly, plumbing connections, and testing are key to achieving reliable, leak-free water storage. GRP tanks provide a durable, low-maintenance solution that meets the needs of diverse industrial applications while optimizing cost efficiency and operational performance.

FAQs: GRP Water Tank Installation

Q1: How long does on-site GRP tank installation take?

A: Typically 3–7 days, depending on tank size, site access, and complexity of plumbing connections.

Q2: Can GRP tanks be installed on rooftops or in tight spaces?

A: Yes. Lightweight modular panels allow installation in constrained or elevated locations, provided structural support is verified.

Q3: What maintenance is required after installation?

A: Regular inspections, cleaning every 6–12 months, and checking seals and joints are usually sufficient.

Q4: Are GRP tanks safe for potable water?

A: Absolutely. They meet industry and municipal standards for clean water storage and can integrate with fire protection or irrigation systems.